Basic knowledge of screw assembly

Screw assembly is the process of connecting two or more parts using screws. It is a common method of fastening components in various industries, such as construction, automotive, and electronics.

The basic steps of screw assembly include selecting the appropriate screw size and type, aligning the parts to be connected, inserting the screw into the hole, and using a screwdriver to tighten it securely.

Different types of screws, such as machine screws, wood screws, and self-tapping screws, are used depending on the application and materials being fastened. It is important to use the correct screw size and type to ensure a strong and secure connection.

Proper tightening of the screw is crucial to prevent loosening and ensure the stability of the assembly. Over-tightening can damage the screw or strip the threads, while under-tightening can result in a loose connection.

Regular maintenance and inspection of screw assemblies are important to ensure they remain secure and functioning properly. Properly installed screw assemblies contribute to the overall quality and durability of the finished product.

More news

Plastic extruder is a common plastic machinery. In the process of daily operation of the extruder, there are various failures in the extrusion machine, which affects the normal production of plastic machinery. Below we analyze the failure of the extruder.

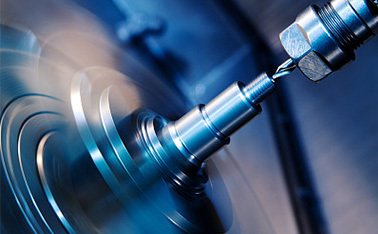

The main part of the pin screw is a conventional screw which can be placed in the groove of the melting section or the metering section of the screw or the smooth cylindrical surface without the groove at the end of the metering section. The pins are arranged in a certain arrangement, and the density can vary from one to another. The cylindrical pin is formed by fitting the pin into the hole of the screw; the square or diamond pin is formed by milling the pin directly on the screw.