News center

A blown film extruder machine is a specialized apparatus widely employed in the plastic manufacturing industry to create plastic films or sheets. These versatile films find applications in various industries, including packaging, agriculture, construction, and more. The working principle of a blown film extruder machine is rooted in the process of extrusion, where plastic material is melted, molded, and cooled to produce a continuous plastic film. Here's an in-depth look at how a blown film extruder machine operates in plastic production:

Injection molding screw heads play a important function in the production realm for diverse reasons:

In the modern plastics processing industry, deciding on a suitable parallel twin-screw barrel is an critical selection to make sure efficient manufacturing and product great. When making this option, several key features need to be taken into consideration to fulfill the varying production needs and complexity of plastic processing strategies.

As a complicated and multi-functional commercial equipment, the flat twin-screw extruder is extensively used in lots of industries, supplying efficient answers for material processing and molding. Here are a few commonplace industries that frequently use flat twin-screw extruders and consequently gain from their advanced generation and flexibility.

WPC parallel twin screw plays an vital role inside the blending process in polymer applications, bringing full-size profits in improving production efficiency, improving product great, and improving the adaptability of the production line. Here’s how WPC parallel twin screws assist beautify key factors of compounding in polymer programs.

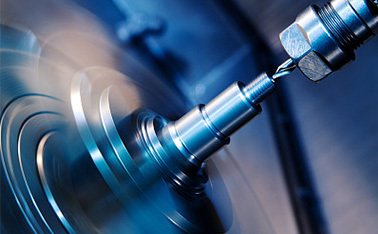

In the realm of plastic manufacturing and extrusion processes, the intricate details of machinery design can significantly influence the outcome of the final product. Among these design nuances, the channel depth of parallel screw barrels emerges as a critical factor with a profound impact on the efficiency and quality of plastic extrusion.

In the realm of polymer processing, the efficiency of material conveyance plays a pivotal role in determining overall productivity. Conical twin barrel screws have emerged as a revolutionary technology, showcasing a unique ability to enhance material conveyance in extrusion processes.

When choosing a high speed Rubber Machine Screw Barrel, a series of key features must be considered to ensure efficient operation, quality production and long-term reliability of the equipment. First, the choice of material is crucial. The screw barrel needs to be made of materials with excellent wear resistance and high temperature stability to adapt to the high-intensity and high-frequency working environment in rubber processing.

Plastic extruder is a common plastic machinery. In the process of daily operation of the extruder, there are various failures in the extrusion machine, which affects the normal production of plastic machinery. Below we analyze the failure of the extruder.

The main part of the pin screw is a conventional screw which can be placed in the groove of the melting section or the metering section of the screw or the smooth cylindrical surface without the groove at the end of the metering section. The pins are arranged in a certain arrangement, and the density can vary from one to another. The cylindrical pin is formed by fitting the pin into the hole of the screw; the square or diamond pin is formed by milling the pin directly on the screw.