Warmly welcome international partners to visit our company for investigation and exchange!

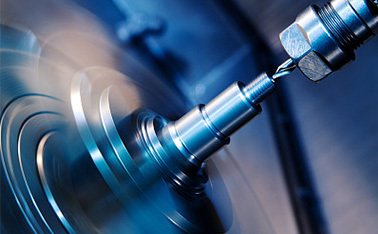

Yesterday, a delegation from foreign machinery industry visited our company to inspect the screw barrel and gearbox production line.

The customers deeply understood the whole process of the products from raw material selection, precision machining to assembly and testing, and highly appreciated our self-developed high-precision screw meshing technology, modular gearbox design and strict quality control system. The two sides reached a number of consensus on customized solutions and overseas market cooperation, looking forward to innovative technology to promote the upgrade of global industrial equipment!

More news

Plastic extruder is a common plastic machinery. In the process of daily operation of the extruder, there are various failures in the extrusion machine, which affects the normal production of plastic machinery. Below we analyze the failure of the extruder.

The main part of the pin screw is a conventional screw which can be placed in the groove of the melting section or the metering section of the screw or the smooth cylindrical surface without the groove at the end of the metering section. The pins are arranged in a certain arrangement, and the density can vary from one to another. The cylindrical pin is formed by fitting the pin into the hole of the screw; the square or diamond pin is formed by milling the pin directly on the screw.