How do WPC parallel twin screws help enhance compounding in polymer applications?

WPC parallel twin screw plays an vital role inside the blending process in polymer applications, bringing full-size profits in improving production efficiency, improving product great, and improving the adaptability of the production line. Here’s how WPC parallel twin screws assist beautify key factors of compounding in polymer programs.

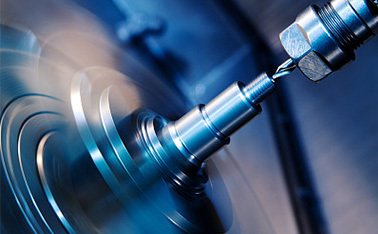

First, the layout of WPC parallel twin screws has made large progress in blending uniformity. Its twin-screw structure is cleverly designed to combine raw substances extra efficiently and make sure uniform distribution of diverse components inside the polymer. In the traditional unmarried-screw structure, because of the confined flow course of the fabric, it is easy to purpose uneven mixing. However, the parallel twin-screw minimizes the occurrence of this hassle and improves the combination uniformity via parallel processing. .

Secondly, the twin-screw structure of the WPC parallel twin-screw enables it to process multiple raw materials on the same time, thus greatly enhancing production efficiency. This parallel processing capability approach that the device can whole extra mixing obligations on the equal time, shortening the manufacturing cycle. Especially within the face of excessive manufacturing call for, WPC parallel dual screws have proven apparent blessings and successfully replied to the fierce market competition.

In addition, WPC parallel twin-screws are usually equipped with superior temperature manipulate systems, that are critical for precise temperature manage throughout polymer blending. Reasonable temperature manage can't simplest save you overheating or overcooling of substances, however additionally assist preserve the stableness of the integration technique. This shrewd temperature control device guarantees solid improvement in product pleasant and reduces variability within the manufacturing technique.

WPC parallel twin screw era is likewise recognized for its sturdy adaptability. The equipment can be adapted to extraordinary manufacturing needs and deal with a whole lot of one of a kind forms of polymers and additives. This flexibility enables manufacturers to better respond to marketplace changes and the range of customer wishes, providing strong aid for the diversification of manufacturing strains.

WPC parallel dual-screw generation performs a key role in the compounding technique in strengthened polymer packages. Through progressed mix uniformity, expanded production efficiency, sensible temperature manage and flexible adaptability, this era provides manufacturers with advanced and comprehensive equipment to higher differentiate themselves in a distinctly aggressive market.

More news

Plastic extruder is a common plastic machinery. In the process of daily operation of the extruder, there are various failures in the extrusion machine, which affects the normal production of plastic machinery. Below we analyze the failure of the extruder.

The main part of the pin screw is a conventional screw which can be placed in the groove of the melting section or the metering section of the screw or the smooth cylindrical surface without the groove at the end of the metering section. The pins are arranged in a certain arrangement, and the density can vary from one to another. The cylindrical pin is formed by fitting the pin into the hole of the screw; the square or diamond pin is formed by milling the pin directly on the screw.