How does Channel Depth Impact Plastic Extrusion Efficiency and Quality in Parallel Screw Barrel Systems?

In the realm of plastic manufacturing and extrusion processes, the intricate details of machinery design can significantly influence the outcome of the final product. Among these design nuances, the channel depth of parallel screw barrels emerges as a critical factor with a profound impact on the efficiency and quality of plastic extrusion.

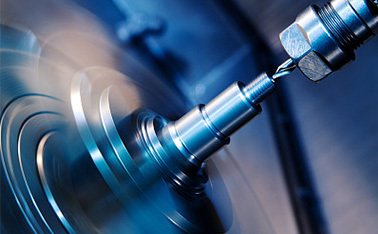

Channel depth refers to the distance between the outer diameter of the screw and the inner surface of the barrel. Essentially, it defines the available space for plastic material within the extruder. Striking the right balance in channel depth is crucial for achieving optimal plastic flow, ensuring efficient melting, and maintaining a consistent extrusion process.

Achieving an optimal channel depth involves striking a delicate balance. A deeper channel allows for increased material intake, facilitating better compression and melting. However, this comes with its set of challenges. Excessively deep channels can lead to overheating of the plastic material, potentially causing degradation and negatively impacting the quality of the final product.

One of the primary objectives in plastic extrusion is to achieve a homogeneous melt. The channel depth plays a pivotal role in this regard. An appropriately designed channel allows for efficient mixing and melting of the plastic, ensuring that additives, colorants, and other components are uniformly distributed.

While a deeper channel promotes better compression and melting, it also raises concerns about heat buildup. Excessive heat can not only lead to material degradation but can also pose challenges in terms of equipment durability. To address this, cooling systems are often integrated into the extrusion machinery, helping to regulate temperature and maintain optimal operating conditions.

Optimizing channel depth contributes to energy efficiency in plastic extrusion. By ensuring an efficient compression process, manufacturers can achieve higher throughput with reduced energy consumption. This not only has economic implications but also aligns with the growing emphasis on sustainability in manufacturing practices.

Despite the benefits, challenges associated with channel depth must be addressed. Shear heating, a phenomenon where intense heat is generated due to the movement of the plastic within the extruder, is a common issue. Manufacturers tackle this by employing materials with high thermal stability and incorporating advanced cooling mechanisms into the system.

An optimized channel depth not only improves the quality of the extruded product but also contributes to the overall reliability of the machinery. Well-designed parallel screw barrels with carefully considered channel depths are less prone to wear and tear, leading to reduced downtime and maintenance costs.

In the dynamic landscape of plastic extrusion, the significance of channel depth in parallel screw barrel design cannot be overstated. Striking the right balance ensures efficient plastic flow, enhances material homogeneity, and contributes to the energy efficiency of the process.

More news

Plastic extruder is a common plastic machinery. In the process of daily operation of the extruder, there are various failures in the extrusion machine, which affects the normal production of plastic machinery. Below we analyze the failure of the extruder.

The main part of the pin screw is a conventional screw which can be placed in the groove of the melting section or the metering section of the screw or the smooth cylindrical surface without the groove at the end of the metering section. The pins are arranged in a certain arrangement, and the density can vary from one to another. The cylindrical pin is formed by fitting the pin into the hole of the screw; the square or diamond pin is formed by milling the pin directly on the screw.