Service support

FAQ

I have the following three options for dealing with the problem of spotting on chrome plating:

I. Upgrade the screw plating (fundamental measures):

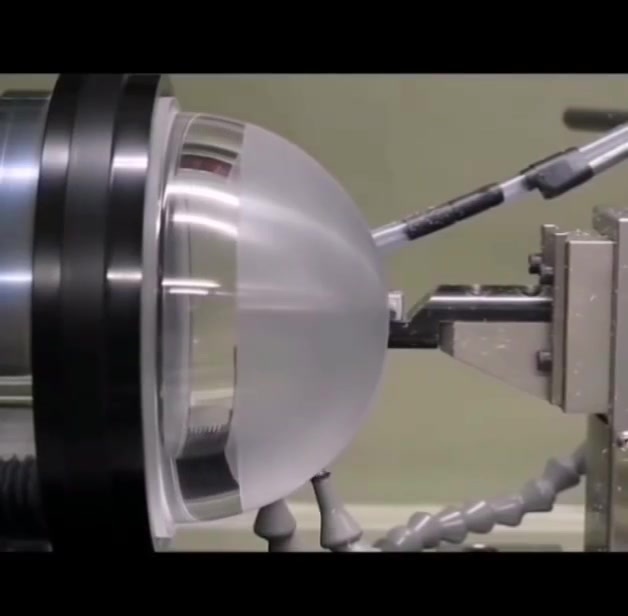

1. Chemical nickel-phosphorus (Ni-P) plating: HCl corrosion resistance is better than chromium, no cracks (recommended thickness ≥ 50μm).

2. Composite plating: bottom nickel plating + surface chrome plating (reduce crack exposure) or nickel plating + PTFE (anti-adhesion).

3. Sprayed tungsten carbide (WC-Co): high hardness and complete corrosion resistance (high cost, suitable for long-term production).

ii. Formulation and process optimization:

1. Replacement of sulfur-containing stabilizers: switch to methyltin or rare earth stabilizers (sulfur-free).

2. Control the melting temperature: under the premise of ensuring plasticization, reduce the temperature to 180-190℃. The production of soft PVC at this temperature is completely feasible, but must meet:

✅ Formulation: low polymerization resin + high efficiency plasticizer (≥ 50phr) + methyl tin stabilizer + composite lubrication system

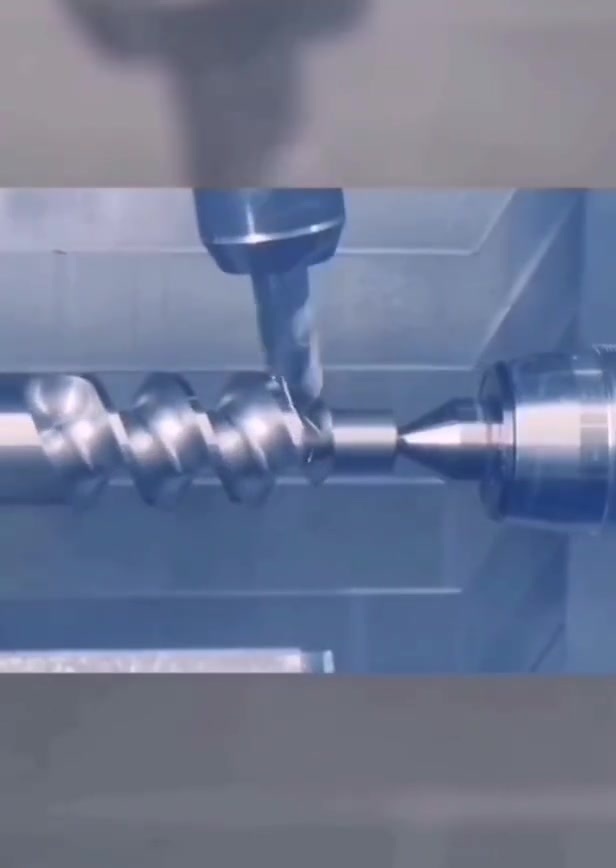

✅ Equipment: optimize the screw structure (compression ratio of ≤ 2.5:1) + strengthen the cooling of the feed section

✅ Process: Appropriate increase in rotational speed and backpressure, add ACR processing aids

3. Shorten the downtime: downtime> 30 minutes Need to clean the screw with LLDPE and apply high-temperature antirust grease.

iii. Adjust the process parameters:

1. Reduce the processing temperature (reduce decomposition under the premise of plasticization).

2. Avoid long time holding downtime, use LLDPE or special cleaning material to clean the screw before downtime.

Yes, we mainly make customized products. We develop and produce products according to drawings or samples provided by customers.

Our products cover almost the entire equipment manufacturing industry and plastic processing applications, mainly insulation board, pipe, sheet and plastic bag industries.

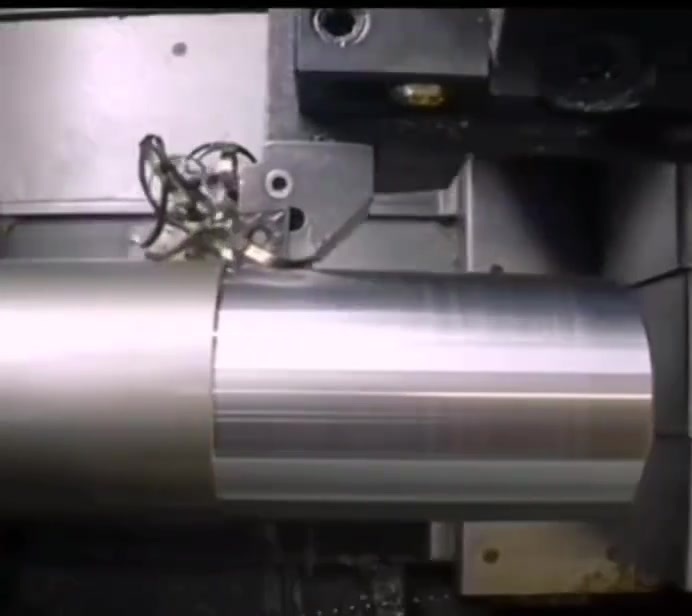

We mainly produce barrel screw and mechanical equipment.

We are a processing plant. At the same time, we have our own international trade department. We produce and sell our own products.

We will reply to you within 12 hours after receiving the inquiry during the working day.

We are a manufacturer and have also established a trading company.

We apply alloy spraying on the surface of the screw to improve wear resistance and service life.

Timely production of goods according to customer needs, quickly reducing delivery time.

We use wooden or cardboard boxes for packaging according to the different goods, and transportation can be done by air, land, or sea.

Yes, the price will be modified based on the quantity of your order.

Write us a message and we will answer you.

If you have any questions about our products or services, feel free to reach out to customer service team.